When is the Best Time to Invest in Direct-to-Screen?

Asking which is the best, is like trying to decide which child is the favorite (we do have one but as its usually the password child, we don’t admit it).

Direct to screen falls into three distinct categories

- Inkjet

- Wax

- Laser

Inkjet has been around for a long time now, with some of the big units costing more than the actual press, they were seen as the new revolution in screen making as they made the whole process of making screens digital.

Printing directly onto the emulsion was revolutionary and removed two stages of the process, the film output, and the placement. The side issue with printing directly onto the emulsion with a light blocking liquid was the small amount of spread we experienced. When the liquid was ejected from the inkjet nozzle it landed on the emulsion and spread ever so slightly, this resulted in a certain amount of dot gain, the dot on the screen was larger than the dot in the art. We could compensate for this with artwork manipulation and calibration curves in the output device or RIP.

A wax printer, also known as a solid ink or phase change printer, works by melting solid ink blocks and applying them to the screen. The ink is heated to a liquid state and then transferred onto the screen using a print head. The ink quickly solidifies as it cools, creating a perfect reproduction of the original image. As the hot ink hits the cold screen, it solidifies and therefore avoids the image spread associated with inkjet systems. Typical resolution is 600dpi

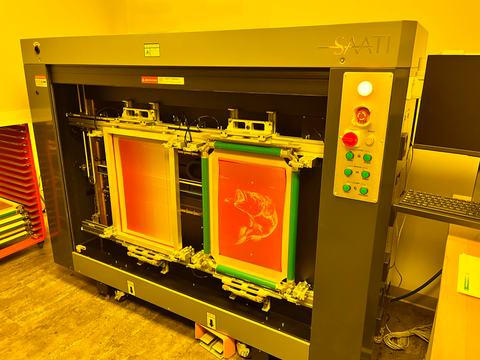

Laser to screen, this is the new kid on the block (an old reference that may need explaining ‘step by step’.) this process uses light to ‘write’ the image directly onto the emulsion.

This process removes one more process as the screen is imaged and exposed in one step. The systems are either direct laser or DMD chip. The DMD (Digital Micro-Mirror Device) systems use an array of tiny mirrors to project the image onto the screen, which provides excellent resolution and accuracy. These systems are suitable for printing high-resolution images, fine lines, and small text.

This system is the future as it reduces one step in the procedure and has zero consumables or waste. It also lets us have resolution up to 2450 dpi!

All three systems provide distinct advantages from printing out film and aligning onto a light source with a vacuum and glass.

One advantage that all systems share is the ability to digitally store and recall images. The old analog printed out transparency, now becomes a digital file that is stored, catalogued, and can be recalled and searched with superhuman accuracy. For those of us old enough to remember the ‘Filing Cabinet of Doom” a space where we would store all previous films, this grey portal was a relative dimension in the normal fabric of space time, a set of 6 immaculate films would be placed in this ubiquitous receptacle on a Monday, only to be transformed into 5 or 7 dog eared scuffed pieces of old cling film by Wednesday, and if you were the one to search here for a set of films you would become affected by the strange warping of time associated with this filing cabinet from another Parallel Universe. Easily losing hours searching for a film that you could have sworn you put in here only one hour ago.

Workflow can be streamlined using digital versions of films to easily plan the sequence of jobs to be prepped next.

The removal of a transparent carrier and the removal of the glass and vacuum can dramatically reduce the imperfections often found when the unidentifiable bodily fluids of the screen goblin magically find their way onto the film, glass and eventually the stencil.

Investing in DTS (Direct to Screen) eliminates the post developing touch up area!

As soon as we relinquish control of the placement of the image and we let the cold digital mathematical brain of the system decide where the image should be placed, we acquire a new power-up we did not realize we needed. The accurate placement in relation to a standard point on the screen will now give us a constant that was not present before, we can utilize this new gift on the press itself. Using the same standard placement point, we can reduce (or eliminate) the time and skill used to align multiple screens on press

The best time to invest in direct to screen equipment depends on your business needs and budget. If you are experiencing growth in your screen printing business and need to increase your production capacity, then it may be the right time to invest in direct to screen equipment. However, if you are just starting out, it may be best to wait until you have established a solid customer base and have enough demand to justify the investment.

My magic number which has zero basis in actual fact but relies purely on the instinct of an old printer is 50 screens per day. If we are constantly making 50 screens per day we can justify the purchase of a machine that eliminates parts of the process.

Article written by Tony Palmer, Palmprint

Tony has more than 30 years experience in garment decoration ranging from manual screen printing on hand carousels to the operation of multi-color automatic presses. Specifically Tony is an expert on MHM Automatics, Tesoma, Exile Spyder, Douthitt CTS, Zentner, and numerous manufacturers of textile decorating equipment.